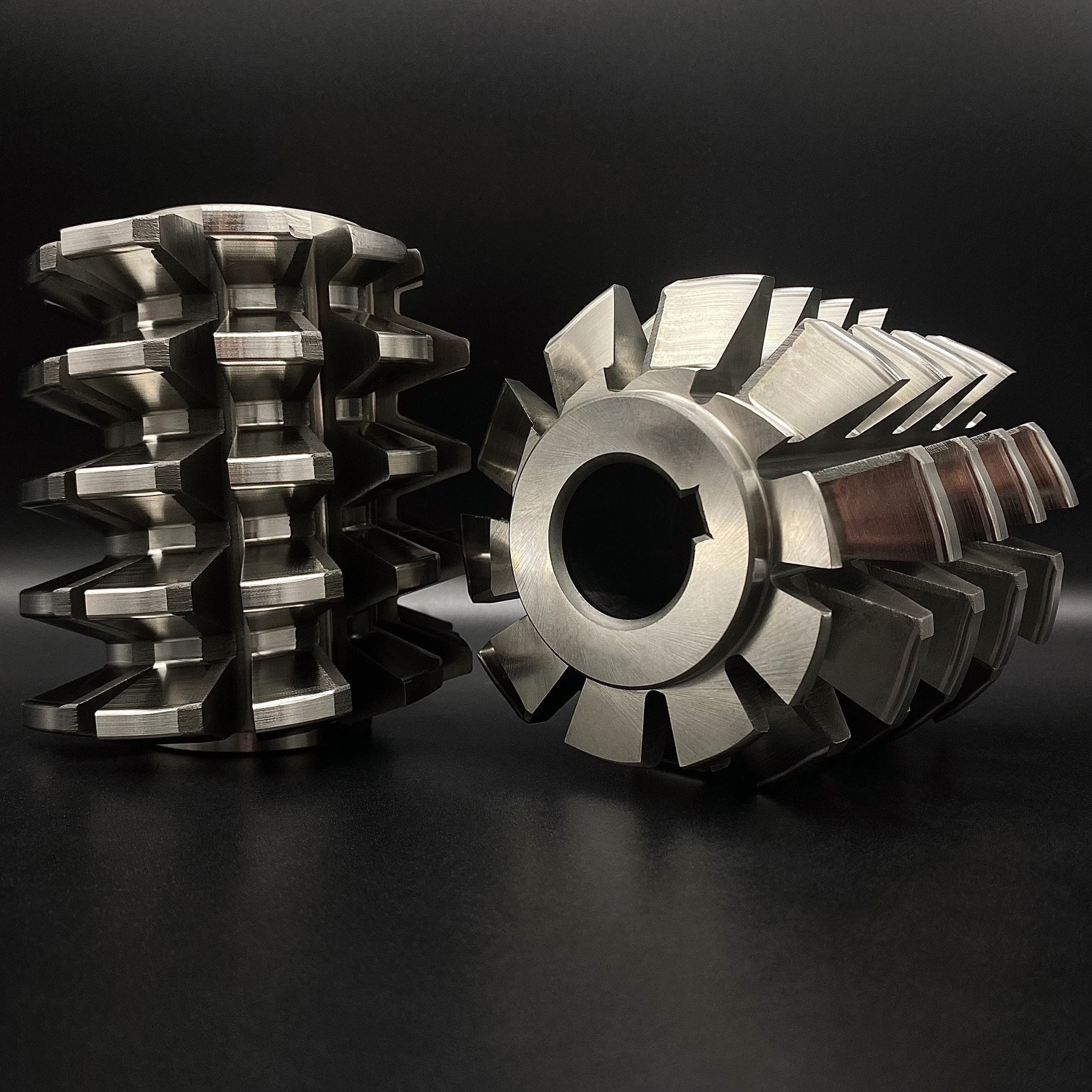

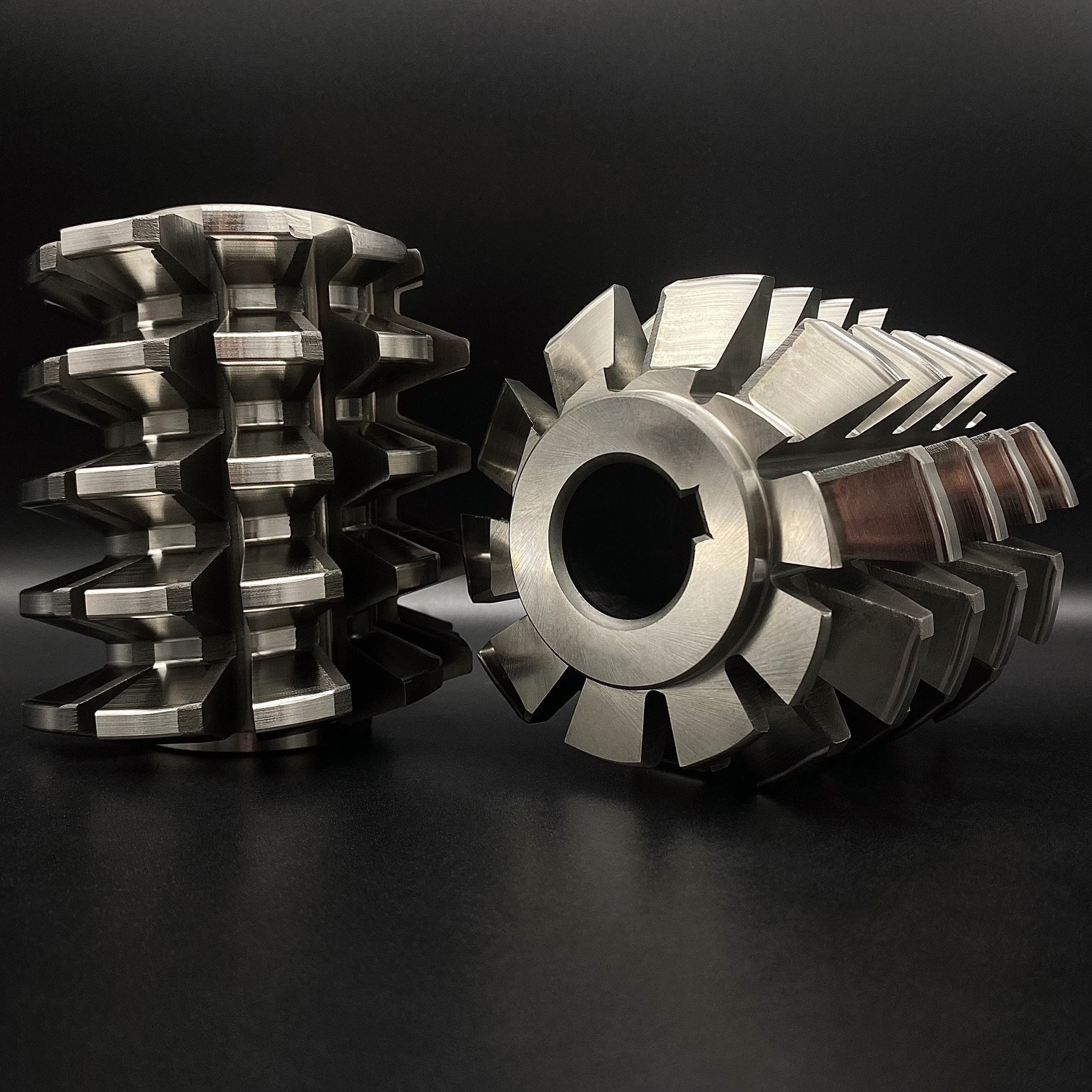

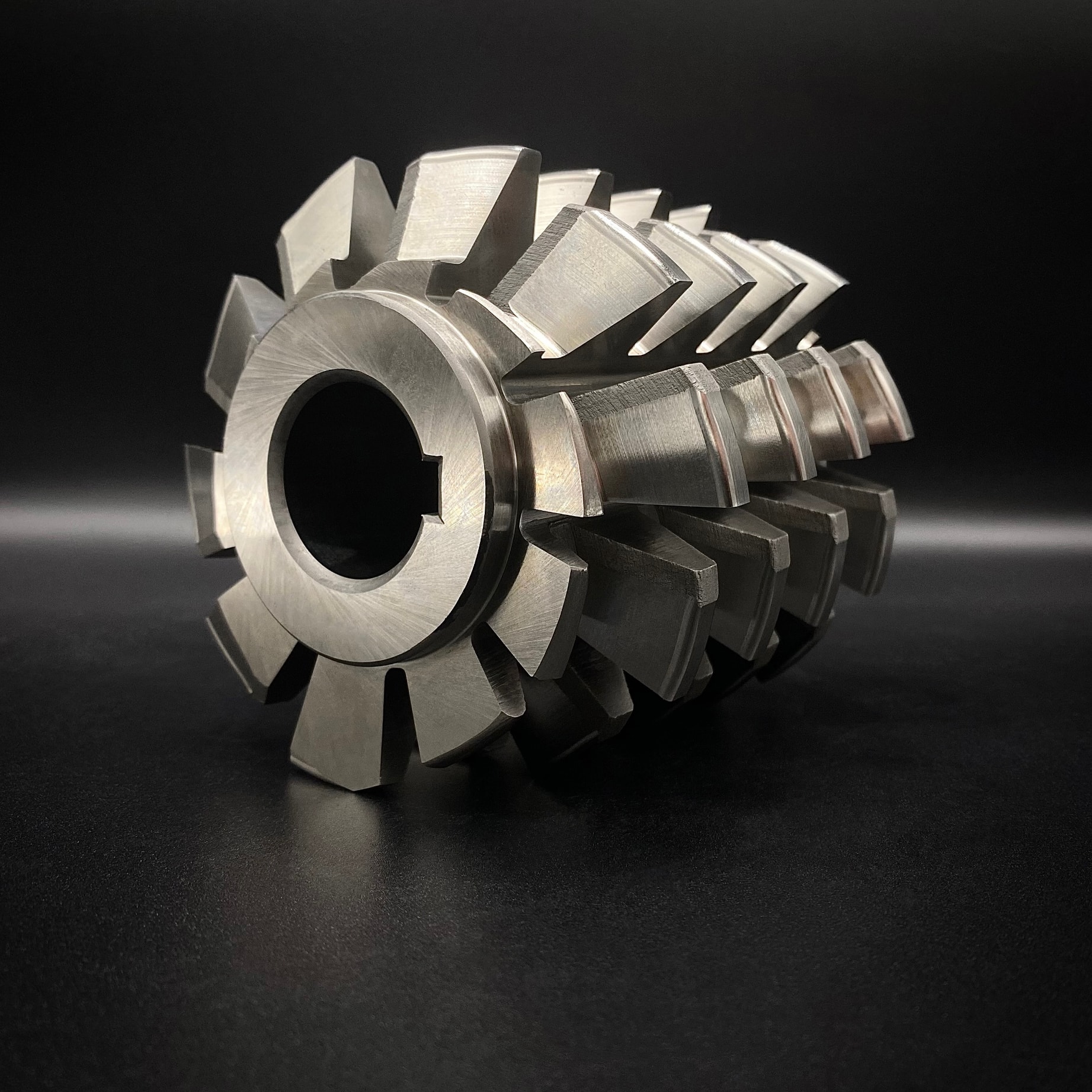

Our hobs are the perfect tools for manufacturing gears with precision and efficiency. Whether you need to create spur gears, helical gears, straight or involute splines, sprockets, or worm gears, our hobs offer exceptional cutting performance and accuracy. With their specialised tooth profiles and advanced design, these tools ensure superior gear manufacturing results.

At Special Tooling, we specialise in producing gear hobs for various gear types and applications. With our extensive range, we can provide solutions for different gear profiles, pitch ranges, and pressure angles. Whether you require pre-shaving gear hobs, straight or helical spline hobs, or specialised hobs for specific applications, we have the expertise and capabilities to meet your gear manufacturing needs.

Our gear hobs are crafted with precision and attention to detail. We utilise high-quality materials and advanced manufacturing techniques to ensure optimal performance, longevity, and accuracy. With our hobs, you can achieve precise gear tooth profiles, excellent surface finish, and reliable gear meshing. Trust our hobs to deliver exceptional results in your gear manufacturing processes.

A gear hob, by design, could be described as a series of rack cutters arranged in a spiral pattern on a cylinder. They are the preferred cutting tool for mass production, as they can cut gears much faster than traditional rack cutters. They are designed to be used in a hobbling machine to cut the specific shape and size of teeth, providing the necessary clearance and tooth form.

No, hobs are typically used for external gear cutting. For internal gear cutting, other methods such as shaping or broaching are commonly employed. These methods involve specialised tools and processes designed specifically for cutting gears with internal teeth.

It is the process of creating teeth on gears using specialised tools. This process is necessary to generate the gears' teeth to the required size, shape, and profile.

Gear cutting tools like hobs, milling cutters, and shaping cutters. These tools are used to accurately cut teeth on gears during the cutting process.

The maximum size that can be produced depends on the specific machine and tooling used. Different machines and tooling have different restrictions on the size and diameter of hobs they can accommodate.

These are special hobs designed for producing teeth on sprockets.

These are cutting tools used for machining the teeth of worm gears.

Coatings provide increased tool life, improved surface finish, reduced friction, and improved chip evacuation.

Have a question? Need a quote? Drop us a message. We will get back to you within 24 hours.