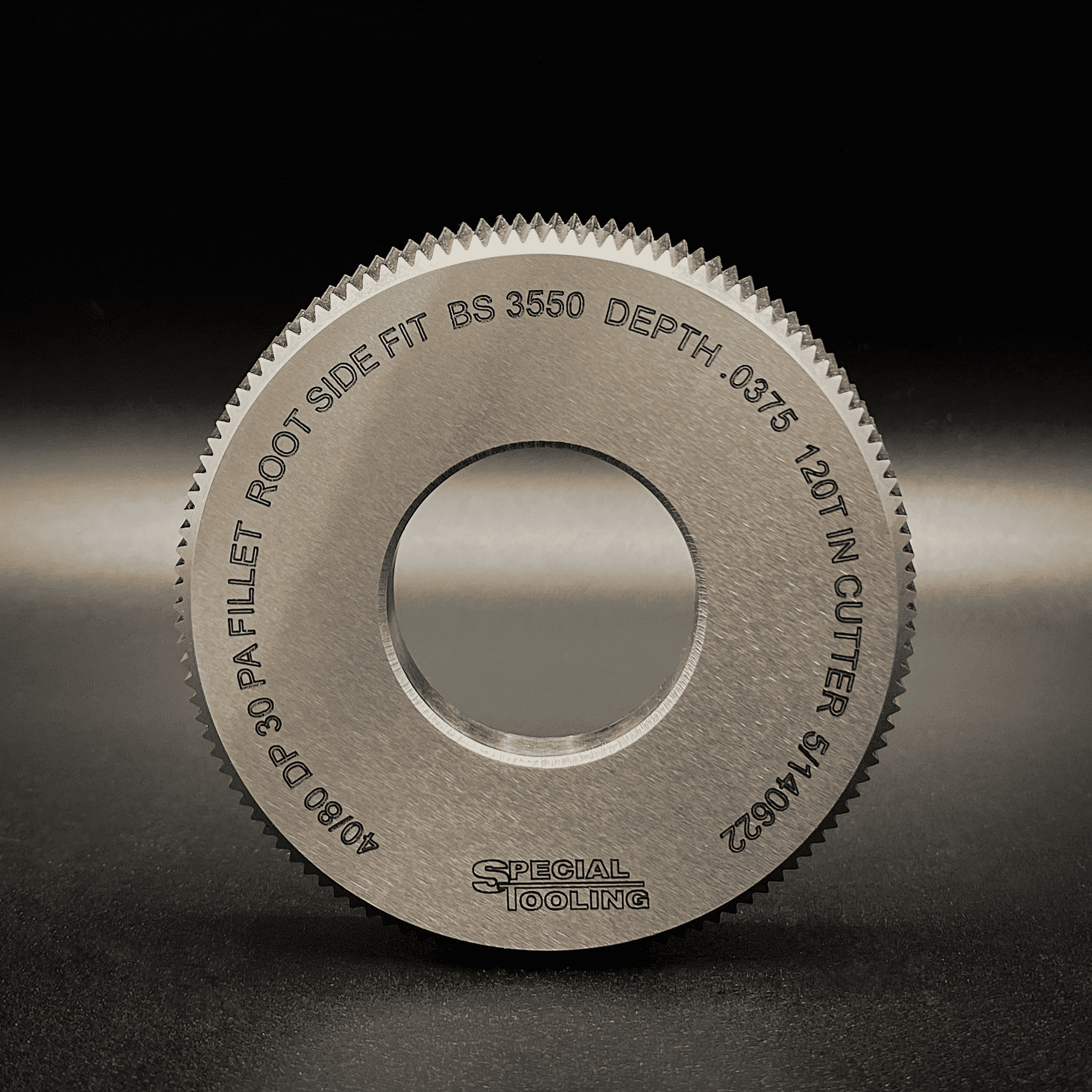

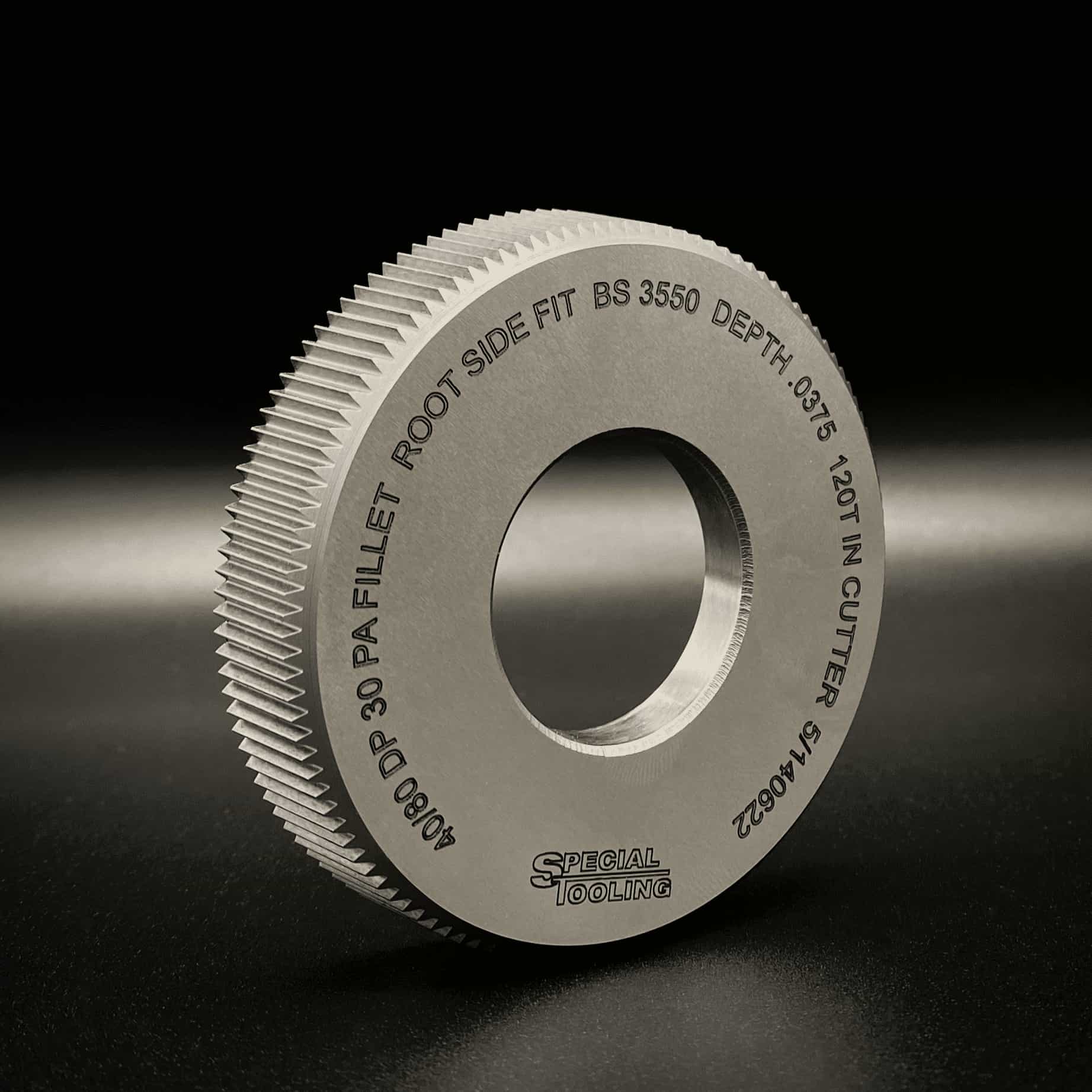

Our disc type cutters are the perfect solution for precision cutting of gears and drives. Designed with utmost attention to detail and engineering excellence, these products deliver exceptional performance and longevity. Crafted from high-quality materials, our cutters possess superior strength and durability. This ensures that they can withstand the toughest machining conditions and deliver consistently high-quality results. Their design and construction also minimizes maintenance requirements, allowing for uninterrupted operation and increased productivity.

This type of shaper features advanced tooth forms that ensure precise gear shaping. With their unique tooth profiles, they enable smooth and efficient machining, resulting in accurate generated teeth and reduced tooth-to-tooth error. This ensures optimum gear performance and quiet operation, making them ideal for applications where precision and noise reduction are crucial. This product is available in a wide range of sizes and configurations to meet the specific requirements of different cutting tasks. Whether it's spurs, helicals, or pulleys, these cutters can handle them all with precision and ease. Additionally, they are compatible with different shaper machine models, making them versatile and adaptable to various machining setups.

With their exceptional shaping capabilities, our disc cutters are suitable for a variety of industries including automotive, aerospace, power generation, and more. They are widely used for gear manufacturing, modification, and repair applications. Their reliability and performance have made them a trusted choice for many gear manufacturers and machining professionals. Invest in our gear shaper cutters for superior results and experience precision, durability, and efficiency.

Disc type shaper cutters are cutting tools for cutting a specific type of gear, either internal or external, spur or helical. They are often used in industries such as automotive and manufacturing.

Disc type shaper cutters have a disc-like shape, hence the name. They are commonly used for cutting involute forms and are designed to achieve a high level of accuracy and precision in the cutting process.

It is the process of creating teeth on gears using specialised tools. This process is necessary to generate the gears' teeth to the required size, shape, and profile.

Yes, they are manufactured according to specific standards, such as BS 5246:1976 and BS 2887(1957). These standards define the dimensions, tolerances, and other specifications for the cutters.

They are typically made of high-speed steel (HSS) and other high-quality tool materials. The choice of material depends on factors such as the type of gear being cut, the required quality and accuracy, and the customer's specific requirements.

They are available in a wide selection of sizes. Depending on the size of the bore and number of teeth, options may vary depending on the manufacturer and the specific requirements of the customer. All pitches are available from .25 pitch to 18 MOD. Most bore sizes can also be accommodated.

Even though these products are capable of being manufactured to various accuracy classes, Class AA is what we usually manufacture as standard. The choice of accuracy class depends on the application and the desired level of precision and quality.

They are designed to achieve a high-quality surface finish on the gear being cut. The exact finish will depend on factors such as the material being cut and the cutting parameters used.

Yes, they can be used for cutting splines. They are suitable for both internal and external splines and can be designed to meet specific spline profiles and dimensions.

Disc-type cutters are made from high-quality tool steel, typically M35 grade. This material provides excellent hardness and wear resistance, making it suitable for cutting operations.

Yes, these products can be supplied with different pitches to meet the specific requirements of your project. Make sure to specify the desired pitch when placing your order.

Yes, we offer custom disc-type shaper cutters to cater to your unique machining needs.

We offer disc-type shaper cutters with various coatings to enhance their cutting performance and tool life. Popular coating options include ALCRONA, MAXIMIZER, and TiN (Titanium Nitride).

Yes, we can supply our products to customers worldwide. Contact us to discuss your requirements and arrange international shipping.

Have a question? Need a quote? Drop us a message. We will get back to you within 24 hours.